25-35 TPH Output Small Production Mechanical Cone Crusher Low Speed

Operation

Introduction

The cone crusher is a crucial equipment in the field of raw

material crushing, widely used in various industries such as

cement, mining, and metallurgy. This powerful machine plays a

significant role in reducing large-sized raw materials into

smaller, manageable particles, ensuring efficient downstream

processing and production.

Overview of Rotary Cone Crusher

A mechanical cone crusher, also known as a slow-speed cone crusher,

operates by rotating the cone-shaped crushing chamber, which is

lined with durable concave and mantle surfaces. The raw material is

fed into the top of the chamber and gradually compressed and

crushed as it moves towards the bottom, where the smaller-sized

crushed material is discharged.

Device Parameters

| Model | XCLA-1800(s) |

| Maximum feed side length | 110mm |

| Average feed size | <50mm |

| Discharge adjustment range | <5mm |

| Production capacity | 25-35t/h |

| Power | 18.5kW |

| Speed | 8-25r/min |

| Weight | 12.6t |

Key Features and Benefits

Efficient Crushing Mechanism: The mechanical cone crusher utilizes

a slow-speed crushing action, allowing for a more effective and

controlled reduction of raw materials. This results in higher

quality end products and improved overall operational efficiency.

Versatile Applications: This type of crusher is suitable for a wide

range of raw materials, including limestone, shale, gypsum, and

many types of ores. It can handle both hard and soft materials,

making it highly versatile in different industries.

Enhanced Particle Shape Control: The design of the rotary cone

crusher enables precise control over the particle shape of the

crushed material. This feature is particularly important in

industries such as clinker production, where specific particle

shapes are required for optimal performance.

Low Operating Costs: The slow-speed operation of the rotary cone

crusher consumes less energy compared to high-speed crushers. This

results in lower operational costs and reduced power consumption,

contributing to improved cost-effectiveness over the long term.

Robust Construction: Mechanical cone crushers are built to

withstand heavy-duty applications and harsh operating conditions.

They are designed with durable components and materials, ensuring

reliable performance and minimizing maintenance requirements.

Easy Maintenance and Accessibility: The design of the mechanical

cone crusher facilitates easy access to key components, simplifying

maintenance tasks. This allows for quicker servicing and reduces

downtime, keeping the overall operation running smoothly.

Equipment Main Parameters

1. The production capacity of this mechanical cone crusher is 25-35

tons per hour, which is a small-capacity equipment.

2. The weight of this mechanical cone crusher is 12.6 tons. The

whole equipment runs smoothly and the speed is low.

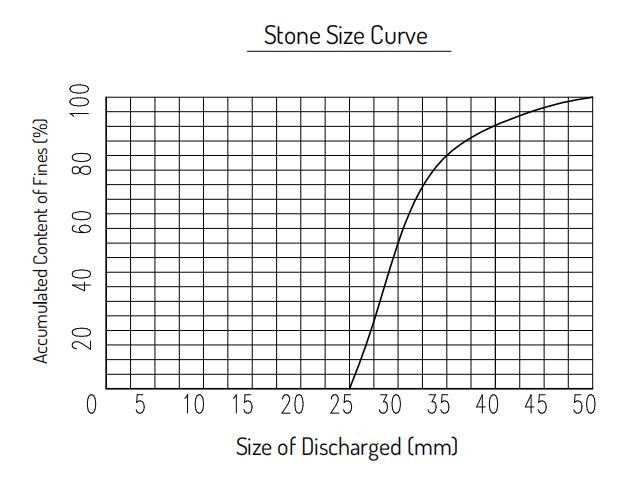

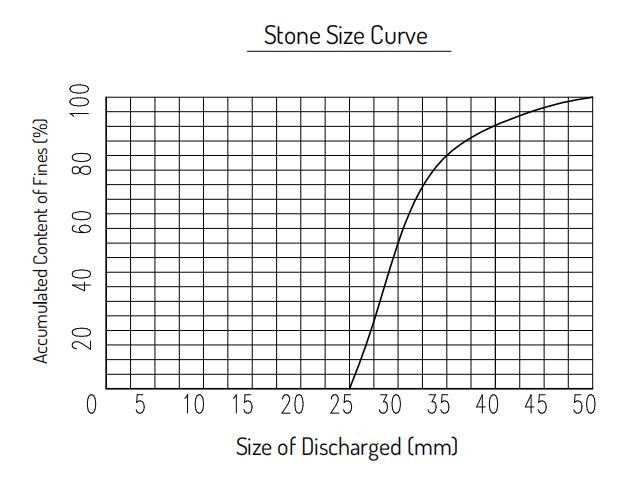

3. The input particle size of this mechanical cone crusher is less

than 50 mm, and the discharge particle size is less than 5 mm. It

is mainly used for the third stage crushing in the mining crushing

production line.

4. The motor power of this mechanical cone crusher is 18.5

kilowatts, and it operates with low energy consumption, reducing

enterprise costs from the perspective of equipment.

Equipment Physical Picture Display