220 Kilowatt Jaw Rock Crusher Large Output 300-800 TPH Production

Capacity

Equipment introduction

This jaw rock crusher is mainly composed of frame, eccentric shaft,

movable jaw body assembly, tooth plate, guard plate, adjusting

seat, toggle plate, tie rod spring, pulley, motor and other

components.

The model of this equipment is XCE1215, which is a model with a

larger output in the jaw crusher series. Its output can reach

300-800 tons per hour, and it is often used in medium-sized and

large-scale mine crushing production sites. Its relevant specific

parameters are as follows:

1. The maximum feed particle size allowed by this jaw rock crusher

is 1020 mm, the size of the feed port is 1200*1500 mm, and the

adjustment range of the discharge port is 150-300 mm.

2. The motor of this jaw rock crusher is an AC motor with a power

of 220 kilowatts. When the equipment is running, its speed can

reach 180 rpm. Slow rotation reduces the wear and tear of the stone

on the equipment and effectively extends the service life of the

equipment.

3. The weight of this jaw rock crusher is 100.8 tons, which is a

heavy-duty jaw crusher.

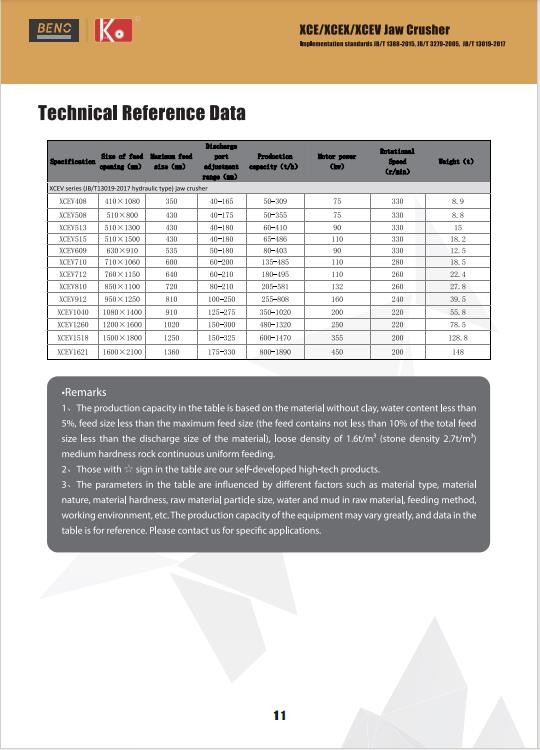

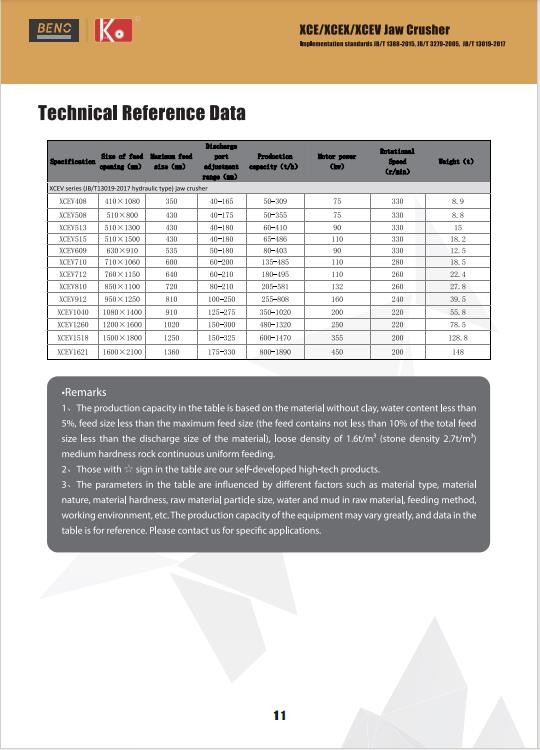

Equipment parameters

| Model | XCE1215 |

| Feed port size | 1200*1500mm |

| Maximum feed side length | 1020mm |

| Adjustment range of outlet | 150-300mm |

| Production capacity | 300-800t/h |

| Power | 220kw |

| Speed | 180r/min |

| Weight | 100.8t |

Equipment application field

Jaw rock crusher is suitable for the following industries:

1. Mining industry: Jaw rock crushers are widely used in the

primary crushing process of ore in the mining industry. They are

capable of processing various types of ores, such as metallic ores

(such as iron ore, copper ore), non-metallic ores (such as

limestone, gypsum), coal mines, etc.

2. Construction and building materials: Jaw rock crushers are used

for stone crushing tasks in the construction and building materials

industry. They can process stone materials of various hardness and

particle size, including marble, granite, limestone, etc., for the

production of building materials, roadbed materials, and concrete

aggregates, etc.

3. Metallurgy: The metallurgical industry uses jaw rock crushers to

initially crush metallurgical ores for subsequent metallurgical

treatment. For example, crushing metal ores into the right size to

extract metals in metallurgical processes.

4. Coal industry: Jaw rock crushers are used in the coal industry

for crushing and pretreatment of coal. They break down large chunks

of coal into smaller particles for better coal handling and

utilization.

5. Construction demolition and recycling: Jaw rock crushers are

used in the construction demolition and waste recycling industries.

They can crush and reuse waste building materials, concrete

fragments, masonry, etc. to reduce waste landfills and

environmental pollution.

6. Other industries: Jaw rock crushers can also be used in other

industries, such as chemical, cement, ceramics, glass, etc. They

are capable of handling a wide variety of materials, crushing and

processing according to the needs of different industries.

Equipment features

Jaw rock crushers possess several characteristics that make them

widely used in various industries. Here are some key features of

jaw rock crushers:

A. High Crushing Ratio: Jaw rock crushers are designed to have a

high crushing ratio, which means that the size of the feed material

is reduced significantly in a single pass. This enables efficient

and effective crushing of large rocks and hard materials.

B. Simple Structure: Jaw rock crushers have a simple and robust

structure, consisting of two main components - the fixed jaw plate

and the movable jaw plate. This simplicity makes maintenance and

repair relatively easy, reducing downtime and ensuring smooth

operation.

C. Safety Features: Jaw rock crushers are equipped with safety

features to protect operators and prevent damage to the machine.

These may include a toggle plate that acts as a safety mechanism in

case of excessive pressure or uncrushable materials.